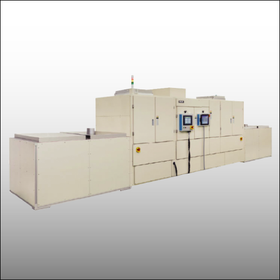

Management of oxide layers on metal surfaces

Quantitative management is possible within the processes of natural oxidation layers and forced heating oxidation layers.

Quantitative management of natural oxide layers and forced heating oxide layers in processes involving copper alloys, aluminum alloys, lead frame materials, and Ni plating is possible. Corona surf is used for managing surface cleanliness and surface quality in various industrial fields. For more details, please download the catalog.

- Company:ナノコート・ティーエス 石川事業所

- Price:Other

![[Application Example] Pulsed Laser Deposition (PLD)](https://image.mono.ipros.com/public/product/image/9dc/2000866190/IPROS46498270375177168683.jpeg?w=280&h=280)